When it comes to material handling, precision and efficiency are crucial. Forklifts, as the backbone of many industrial operations, are equipped with various attachments to enhance their functionality. Among these, side-shifting carriages play a vital role in optimizing load handling. But did you know there are different types of side-shifting carriages? Today, we’ll explore the difference between hang-on side shift and integral (integrated) side-shifting carriages and help you determine which is best for your operation.

What is a Side-Shifting Carriage?

Before diving into the differences, let’s clarify what a side-shifting carriage does. A side-shifting carriage allows the forklift operator to move the forks laterally, either to the left or right, without needing to reposition the entire forklift. This small adjustment capability is incredibly useful in tight spaces or when precise load positioning is necessary.

Hang-on Side-Shifting Attachment

Design:

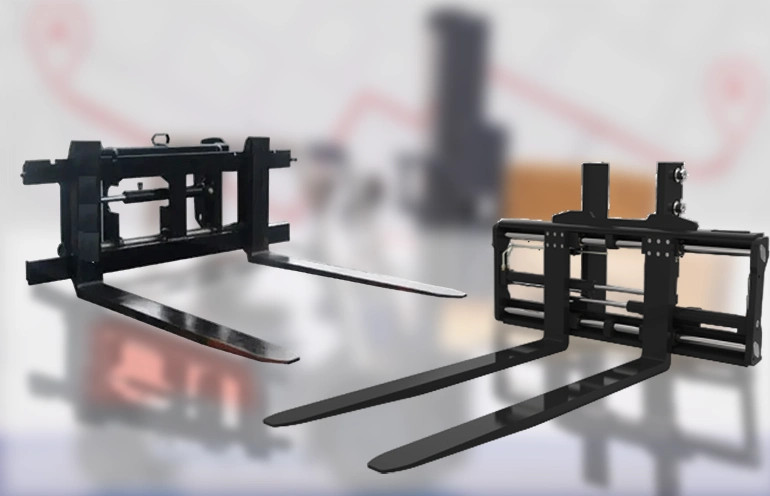

The hang-on side shift is an attachment added to the forklift. It’s mounted

between the forklift’s carriage and the forks, making it an additional

component that can be installed or removed as needed.

Functionality:

This setup allows for the same left-to-right movement of the forks, but because

it’s an add-on, it may require some modifications or adjustments during

installation. The hang-on side-shifter is popular because of its flexibility –

it can be detached if not needed, allowing other attachments to be used in its

place. It can also be considerably less expensive than an integrated carriage.

Considerations:

- Versatility: Because it’s an attachment, the standard side-shifter can be easily swapped out, giving operators more options depending on the task.

- Impact on Load Capacity: The addition of a side-shifting carriage can affect the forklift’s load capacity and center of gravity, so operators must be aware of the load limits when using this attachment.

Integral (Integrated) Side-Shifting Carriage

Design:

The integral side-shifting carriage, on the other hand, is built directly into

the forklift’s carriage. It’s not an add-on but an integrated part of the

forklift’s design.

Functionality:

Like the standard version, it enables lateral movement of the forks. However,

since the side-shifting mechanism is integrated into the carriage itself, it

offers a more streamlined and efficient operation.

Advantages:

- Increased Load Capacity: Because it’s not an external attachment, the integral side-shifting carriage typically supports higher load capacities. This is crucial for heavy-duty operations where every pound counts.

- Reduced Load Center Distance: An integrated side-shifter maintains a closer load center, enhancing the forklift’s stability and reducing the risk of tipping, especially when handling heavy loads.

- Lower Profile and Weight: The design often results in a lower profile and lighter overall weight, which can be beneficial for operators needing maximum visibility and maneuverability.

Which One is Right for You?

The choice between a standard and an integral side-shifting carriage comes down to the specific needs of your operation.

- Choose a Standard Side-Shifting Carriage if you need flexibility and versatility in your attachments. It’s an excellent choice for operations that require frequent switching between different forklift tools.

- Opt for an Integral Side-Shifting Carriage if your priority is increased load capacity, stability, and a more streamlined design. This is often the preferred choice for operations that handle heavy loads regularly and require precision in load handling.

Conclusion

Both standard and integral side-shifting carriages offer valuable benefits, but understanding their differences is key to optimizing your forklift’s performance. By choosing the right carriage for your needs, you can ensure safer, more efficient material handling in your operation.